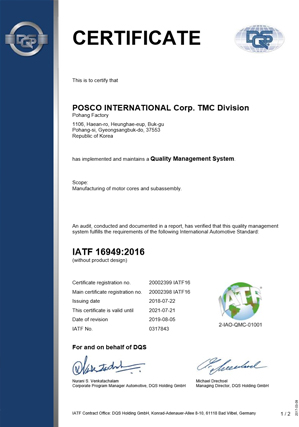

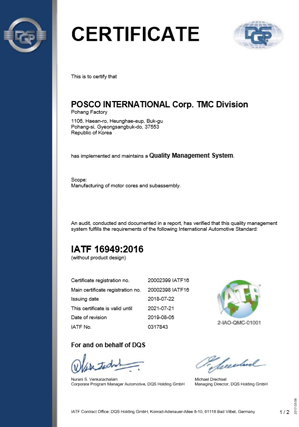

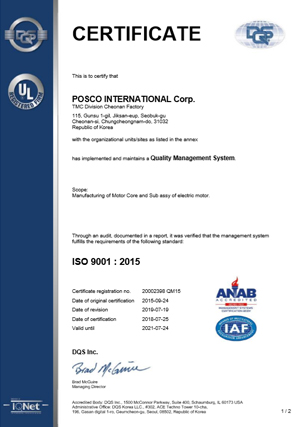

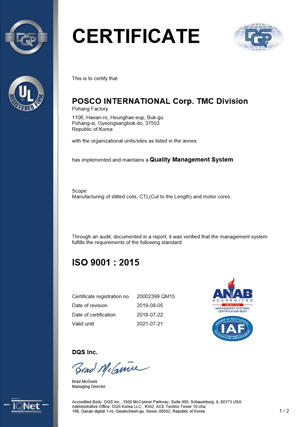

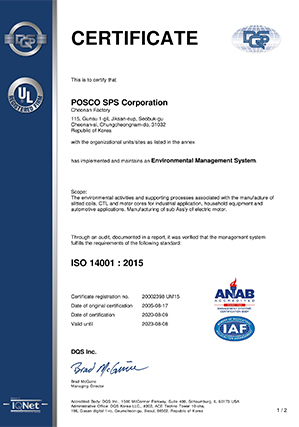

Patents and quality certification

PATENT

The TMC Division develops and supplies small but essential components for not only hi-tech industries, but also everyday life, plays a pivotal role in industrial development, and has numerous patented technologies.

| Type | Title |

|---|---|

| Mold |

|

| Etc. |

|