Definition and Main uses

Definition of Precision Stainless Steel접기

- Ultra thin material with less than 0.3t thickness that only can be produced from a STS precision Mill

- High Hardness/high quality product (i.e. thickness, flatness, hardness) used for automotives, electricity and electronics

| Classification | Dimension | Material | Surface |

|---|---|---|---|

| Precision material | (Ultra thin) 0.1㎜ ≤ t ≤ 0.3㎜ (Super ultra thin, foil) t <0.1㎜ |

Application/customer specific 1/2H, 1/4H, 3/4H, FH |

Customized Dull, surface roughness and gloss |

| STS general cold rolled |

0.3㎜ ≤ t | International/national specification for stainless steel KS, JIS, ASTM, EN |

Standardized surface including 2B and BA |

Main uses of precision STS products

According to the recent trends of weight reduction and miniaturization, the market requires thinner and narrower stainless steel materials. POSCO MOBILITY SOLUTION has the state-of-the-art technologies to meet customer needs and market trends.

POSCO MOBILITY SOLUTION’s stainless steel products possess precise mechanical properties and perfectly managed flatness.

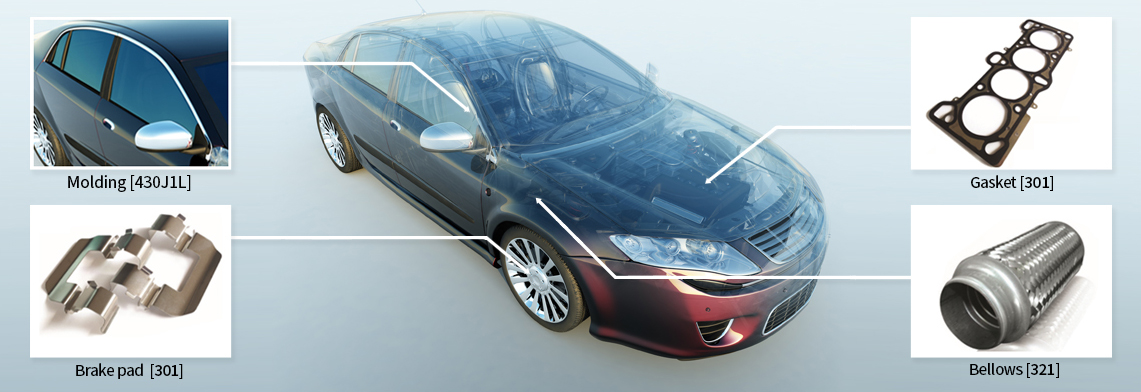

Automotive sector

Engine gasket

The latest development in the head gasket technology is multilayer steel (MLS) design, which has three to seven layers of thin stainless spring steel. MLS head gaskets provide the ultimate in torque retention and give extra strength to support current lightweight engine design.

| Size | 301 [ AR : 0.2~0.25mm ] |

|---|---|

| Application | Automotive engine |

| Quality control |

|

Brake pad spring

The temper rolled stainless spring steel installed in an automotive brake system transfers pressure from the pedal to brake pads. Because of its complicated design, precise thickness and flatness tolerances are required to optimize bending and formability.

| Size | 301 [ AR : 0.4~0.5mm ] |

|---|---|

| Application | Automotive brake system |

| Quality control |

|

Bellows

Bellows are installed in the automotive exhaust system to reduce the noise level and dampen engine vibration. Exhaust bellows by precision stainless steel serve to absorb thermal and vibrational stresses at high temperature, and compensate for misalignment in the exhaust assembly.

| Size | 321/316Ti/309Si [ 2B,BA : 0.15~0.3mm ] |

|---|---|

| Application | Automotive exhaust system |

| Quality control |

|

Molding material

Stainless steel molding materials add visual allure to an automotive exterior. Depending on a vehicle’s design, its surface can be changed in a number of ways to create unique values.

| Size | 430J1L/436L [ BA, Dull, Color: 0.4t - 0.5mm ] |

|---|---|

| Application | Automotive exterior |

| Quality control |

|