New Technology

EMFree

EMFree [Embo-Free] Motor Core

-

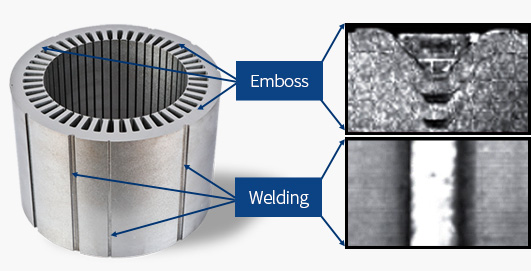

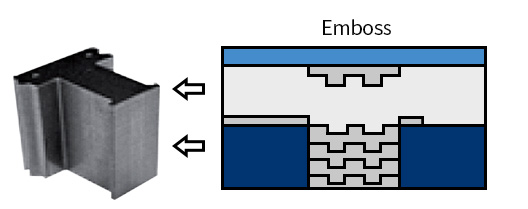

■ Existing technology [Emboss]

Fastened on the surface of electrical steel in relief

- The amount of embossing needs to be increased to reinforce the clamping force.

- Lower efficiency due to the gap between the embossing and the sheet

- Lower flux density due to the deterioration of the stacking factor caused by the gap between individual sheets

- 5~10㎛ between layers

-

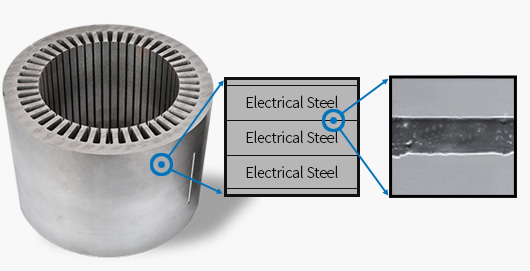

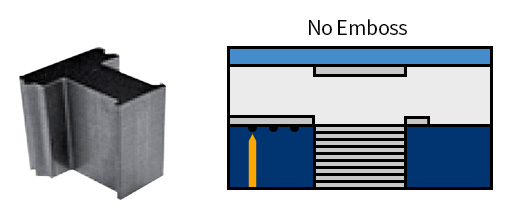

■ New technology [Bonding]

Fastened with adhesive between electrical steel products without any relief, welding or rivet

- Greater clamping force and stacking factor than the Embo type

- 10% less core loss than the Embo type

- Over 15% greater flux density than the Embo type

- 2~3㎛ between layers

Characteristics of the EMFree Motor core

-

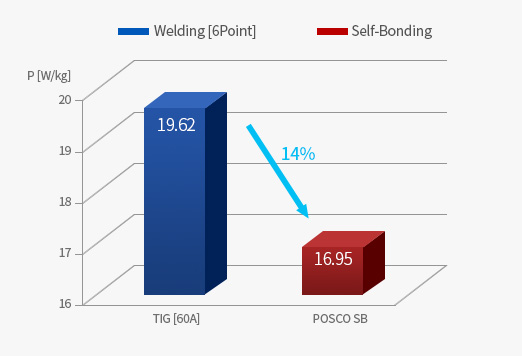

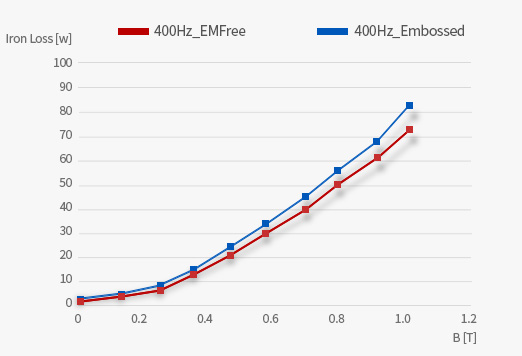

■ Core Loss

-

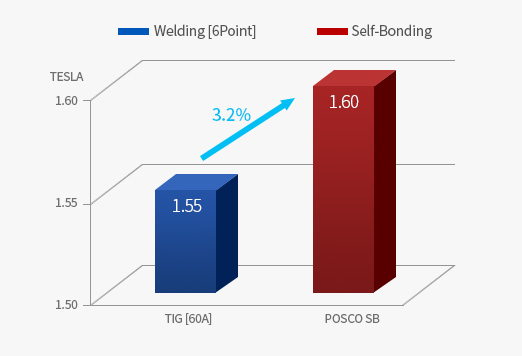

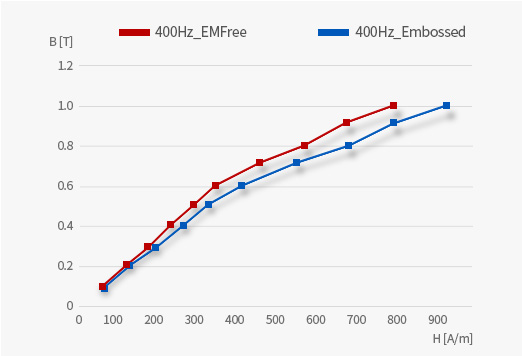

■ flux Density

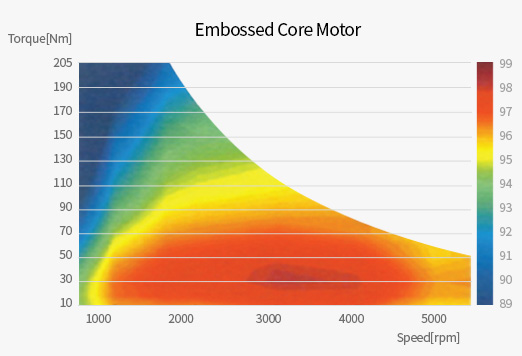

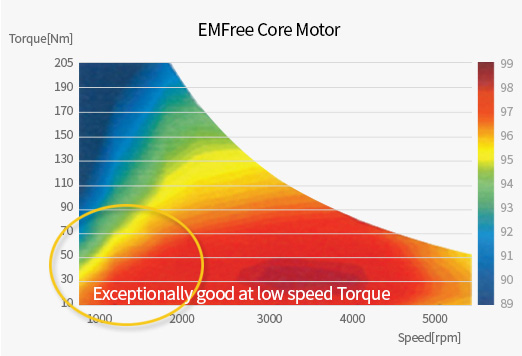

■ Traction Motor Efficiency

The EMFree type has higher torque efficiency than the Embossed Type in the low-speed section.

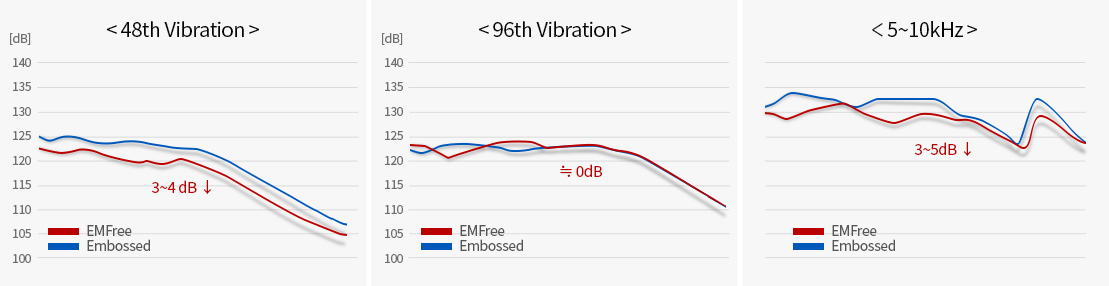

■ NVH evaluation

Results from testing of EMFree motor cores for green cars

| Item | EMFree | Embossed Type | Remarks | |

|---|---|---|---|---|

| Core | Stacking force | 74.04[kgf/㎠] | 3.38[kgf/㎠] | |

| Perpendicularity | 0.126 | 0.308 | ||

| Flatness | 0.054 | 0.306 | ||

| Motor efficiency | - | 0.1~0.3%↑ | - | 2.66 → 2.58kg |

| NVH | High frequency | 3~5dB↓ | - | |

| Environment | Adhesive (high temperature) |

62.31 → 14.22kgf | 3.83 → 3.85kg | 160℃, 80min |

| Adhesive(ATF oil) | 10.23 → 7.71kgf | 2.66 → 2.58kg | ATF150℃, 500hr | |