CTL Core [Cut to Length Core]접기

CTL(Cut to Length) is made by shearing a grain-oriented electrical steel Lamination to manufacture large-sized transformers for industrial uses. POSCO MOBILITY SOLUTION guarantees excellent quality by its own technology and expertise.

CTL (Cut to Length) is an equipment by which grain-oriented (GO) electrical steel is cut to length and used for industrial transformers.

The company features line-ups ranging from small (60mm) to large (1,000mm) equipment, and satisfies customers’ design specifications with high productivity, perfect quality and quick service. Also, it can process both the Normal Type and the Step-lab Type, and has the V-Notching, Tip-Cutting, Hole and Slot-Punching process too.

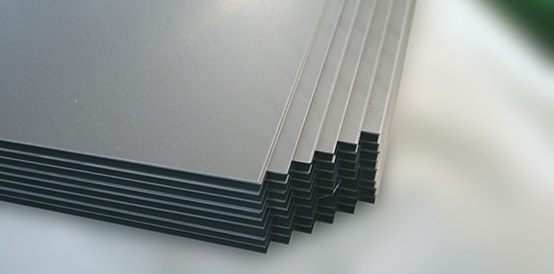

- Normal Type: It means processing to a certain length and stacking. It is mostly used for the small mold transformer or dry transformer.

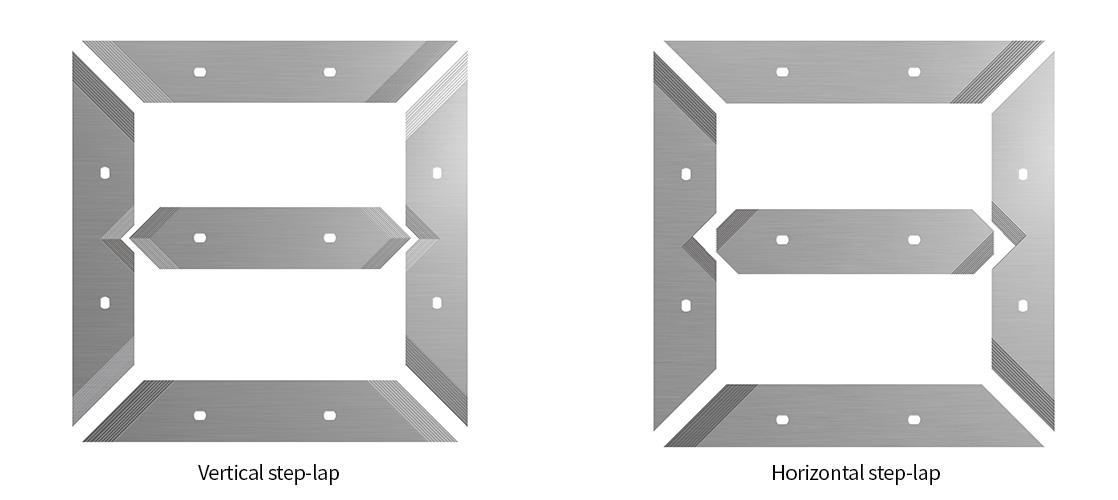

- Step-lab Type : Individual sheets are stacked at a certain interval, It is mostly used for large power transformers, and recently it is also being applied to small transformers to improve efficiency and noise.

CTL core is used widely from small dry and mold transformers to large liquid-immersed extra-high-voltage transformers.

Type & Application

-

- Normal Type

- A method to process and laminate in a designated length for each unit, majorly used for small mold and dry transformers.

-

- Step-lab Type

- A laminating method to give a designated interval between sheets and form a certain layer every in-between, majorly used for large power transformers; however, recently applied to small transformers in order to improve efficiency and reduce noise

Vertical & Horizontal step-lap comparison

Images of the CTL process