Thick Plates Processing and Steel Construction Materials접기

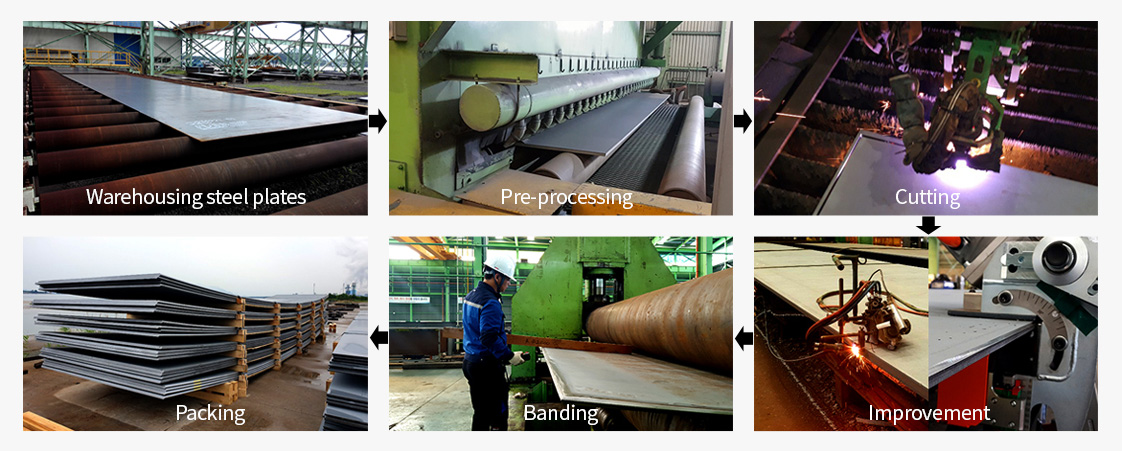

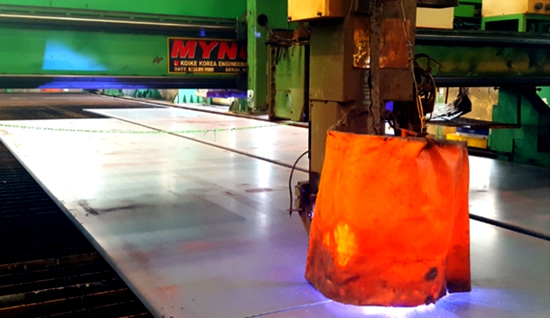

The Gwangyang 1Plant, which is in charge of shipbuilding and steel construction materials, is leveraging a lot as large as 50,000 pyeong, to provide one-stop service from storage of inventor to the raw materials of thick plates and shape steel, pre-processing, cutting, welding and painting. It acquired the cutting processing classification approval [10 classification societies, e.g. BV and DNV] in 2011, and is solidifying its cooperative system with customers by managing the quality of shipbuilding and maritime products more systematically. Also, it has equipment capable of producing 40,000 tons of steel construction materials, built-up beams and steel structures a year, and participates in large projects in Korea and overseas.

Size of the plant: 158,000㎡, factories/office buildings 33,000㎡

Key equipment

[Unit : machine]

| Classification | Equipment name | Qty | Material | Production specs | Production capacity (ton/month) |

||

|---|---|---|---|---|---|---|---|

| Thickness | Width | Length | |||||

| Making steel structures | Fabrication yard | 3 | structure | Fabrication Shop*3(8,300㎡) | 2,500 | ||

| Painting yard | 1 | structure | Blasting Room*1, Painting Room*2 | 1,000 | |||

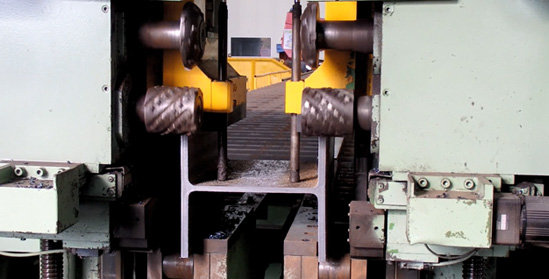

| Shape steel processing equipment | 1 | shape steel | Band Saw*2, Drill M/C*1, Bevel M/C*1 | 1,000 | |||

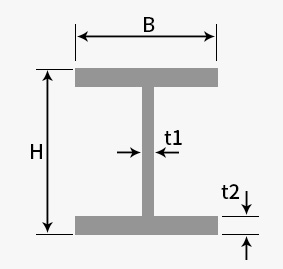

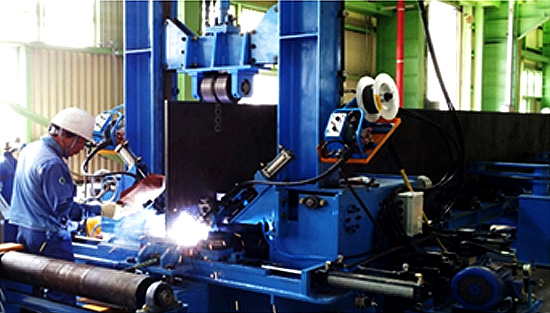

| Built-up H-Beam making | SAW M/C | 6 | shape steel | 8~80 | 3,500 | 18,000 | 2,000 |

| Tank Panel processing | BENDING M/C | 1 | thick plate | 60 | 4,750 | 20,000 | |

| BEVEL M/C | 1 | thick plate | 7~80 | 15~60˚ | |||

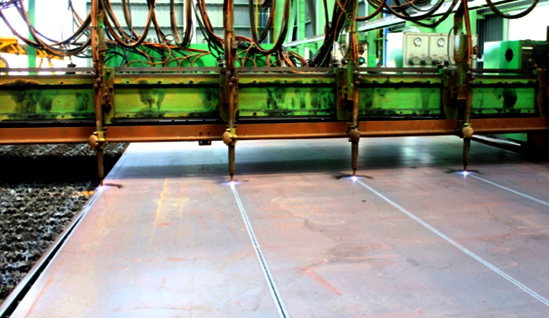

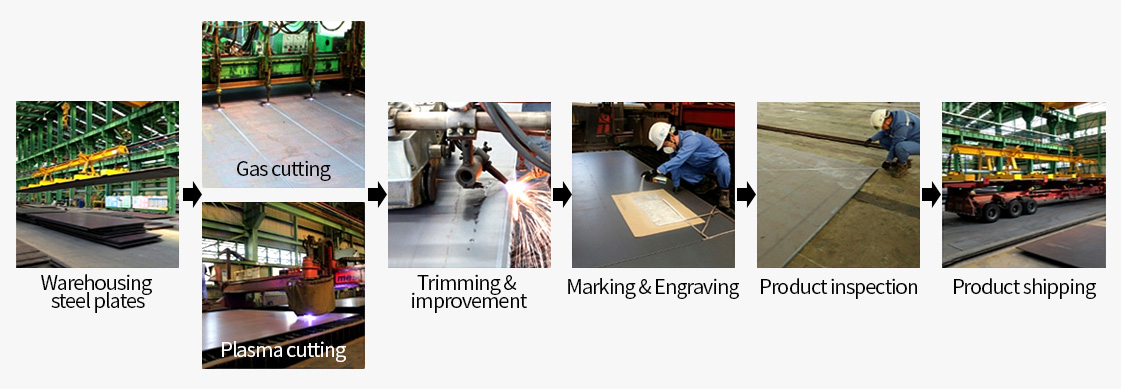

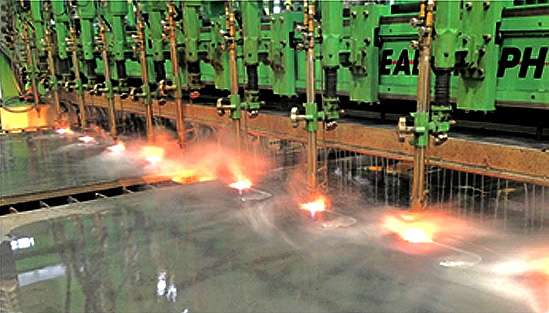

| Cutting | Plant 1 Plasma Cutting M/C | 4 | thick plate | 5~39 | 5,300 | 37,000 | 8,000 |

| Plant 1 Gas Cutting M/C | 3 | thick plate | 5~200 | 5,300 | 23,000 | 4,500 | |

| Plant 2 Plasma Cutting M/C | 4 | thick plate | 5~39 | 5,300 | 37,000 | 8,000 | |

| Plant 2 Gas Cutting M/C | 1 | thick plate | 5~200 | 5,500 | 23,000 | 1,500 | |

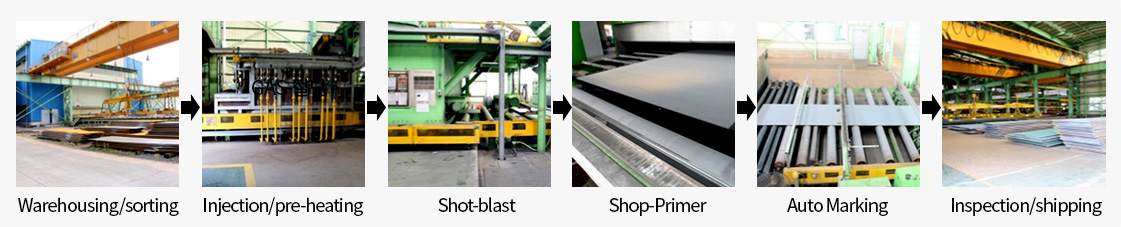

| Pre-processing | Plant 1 automatic pre-processing | 1 | thick plate | 5~90 | 5,300 | 23,500 | 25,000 |

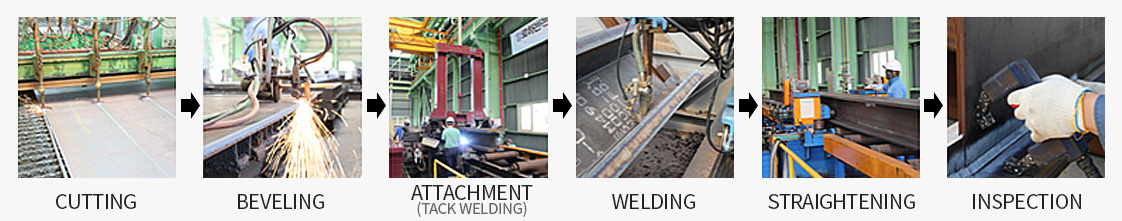

[Making steel frames]

[Making steel frames] [Making steel frames]

[Making steel frames] [Built-up Beam - Fit up]

[Built-up Beam - Fit up] [CNC Gas - Cutting]

[CNC Gas - Cutting]

Steel frame making and painting equipment

Size and production capacity

| Classification | Classification | Production capacity | |

|---|---|---|---|

| Plant 1 | 3,600㎡ [25M x 143M] | 1,000 [Ton/month] | 30,000 [Ton/annual] |

| Plant 2 | 3,000㎡ [25M x 120M] | 700 [Ton/month] | |

| Plant 3 | 2,700㎡ [30M x 90M] | 800 [Ton/month] | |

| Total | 8,300㎡ | 2,500 [Ton/month] | |

Production capacity

Drill M/C [AMADA / 1300Ⅲ]

Drill M/C [AMADA / 1300Ⅲ] BAND SAW [AMADA / HK1300]

BAND SAW [AMADA / HK1300] BAND SAW [AMADA / H750]

BAND SAW [AMADA / H750] Bevel M/C [SHINK / VHP-1255]

Bevel M/C [SHINK / VHP-1255]

| Classification | Production capacity | Remarks | |

|---|---|---|---|

| Thickness | Width | ||

| Drill M/C | WEB : 4.5T ~ 30.0T FLG : 7.0T ~ 50.0T |

WEB : 150 ~ 1,300mm FLG : 75 ~ 500mm |

|

| BAND SAW (H750) | ∞ | 750mm or less | *For processing of 45T or more, consultation is necessary. |

| BAND SAW (HK1300) | ∞ | 1,300mm or less | *For processing of 45T or more, consultation is necessary. |

| Bevel M/C | 6.0T ~ 40.0T | Hshape steel : 250 x 150~1,200 x 500 | 1,200 x 500 *angle : MAX x 35° |

Hole Drilling

Hole Drilling Beveling

Beveling

Painting equipment

| Classification | Details | |

|---|---|---|

| BLASTING | CELL SIZE | 20,000L * 25,000W * 8,000H - 1 |

| WORKING PRESSURE | 7~8KG/㎠ | |

| PAINTING | CELL SIZE | 20,000L * 25,000W * 8,000H - 2 |

| ABRASIVE | STEEL GRIT | 0.5~ 1.0mm |

| Surface roughness | 30 - 75μm SIS Sa2½ (customers’ request) | |

| Film thickness, PAINT | Customers’ specifications request | |